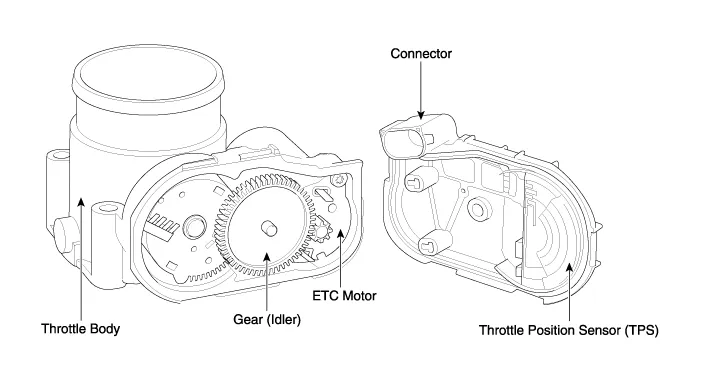

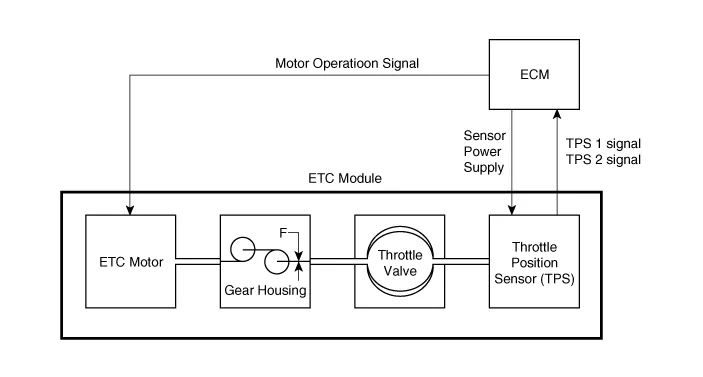

Hyundai Santa Cruz: Engine Control System / ETC (Electronic Throttle Control) System

| Item | Specification | |

| New | Aged | |

| Coil Resistance (Ω) | 1.9 ± 10% | R < 2.8 |

| Item | Fail-Safe | |

| ETC Motor | Throttle valve stuck at 8.15° | |

| TPS 1, 2 | TPS 1 fault | Coping with TPS2 Signal Value |

| TPS 2 fault | Coping with TPS1 Signal Value | |

| TPS 1, 2 fault | Throttle valve stuck at 8.15° | |

| APS 1, 2 | APS 1 fault | Coping with APS2 Signal Value |

| APS 2 fault | Coping with APS1 Signal Value | |

| APS 1, 2 fault | Throttle valve stuck at 8.15° | |

※ When throttle value is stuck at 5°, engine speed will be limited to below 1,500 rpm and vehicle speed to maximum of 40 - 50 km/h (25 - 31 mph).

1.Connect the diagnostic tool to the Data Link Connector (DLC).

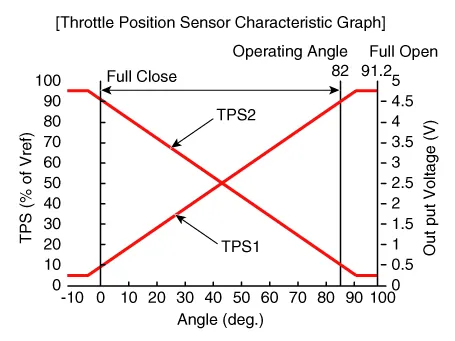

2.Start the engine and measure the output voltage of TPS 1 and 2 at C.T. and W.O.T.

Specification : Refer to "Inspection"

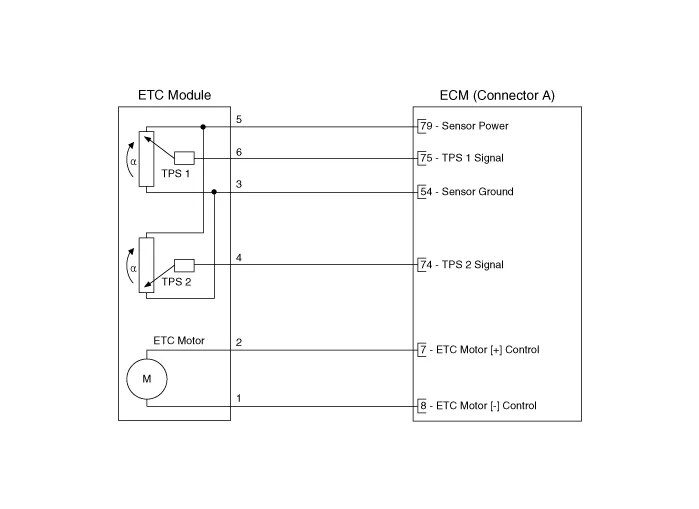

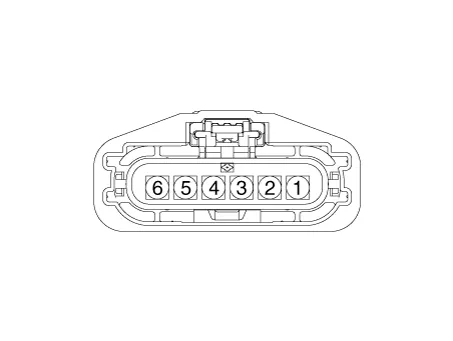

1.Disconnect the ETC module and measure the resistance between the ETC module terminals 1 and 2.

Specification : Refer to "Inspection"

1.Turn ignition switch OFF and disconnect the battery negative (-) cable.

2.Remove the air duct (A).(Refer to Engine Mechanical System - "Air Cleaner")

3.Remove the intercooler inlet hose and pipe.(Refer to Engine Mechanical System - "Intercooler")

4.Remove the intercooler outlet hose and pipe.(Refer to Engine Mechanical System - "Intercooler")

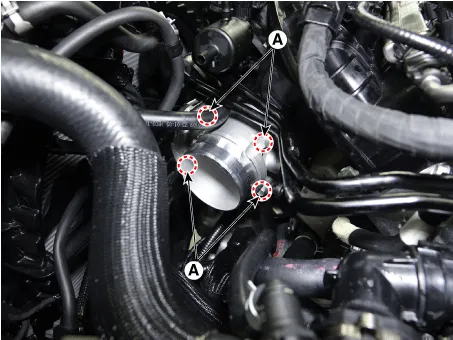

5.Disconnect the ETC module connecter (A).

6.Remove the mounting bolts (A) and then remove the ETC module from the enigne.

1.Remove the ETC Module.(Refer to Engine Control System - "ETC Module")

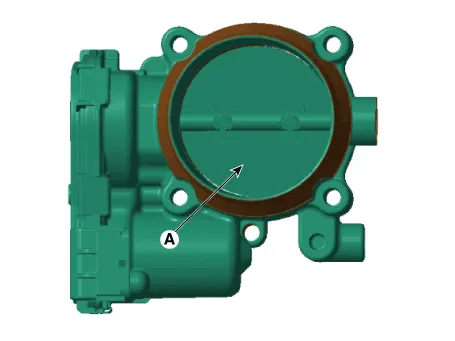

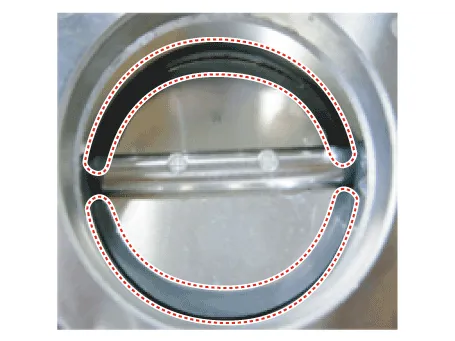

2.Keep the ETC module plate (A) open.

3.Clean the contamination part of the throttle body with a soft and lint-free cloth dampened with cleanser to prevent foreign objects from going in.

• Do not spray a cleanser directly to ETC module. Use a soft and lint-free cloth to clean carbon.

• Be careful not to wipe out coating (A) around the shaft. If the coating is removed, poor idling control can be caused by excessive air leakage or foreign materials in the bearing of the shaft.

4.After cleaning it, reinstall the ETC module and perform ETC module learning procedure.(Refer to Engine Control System - "ETC Module")

• Install the component to the specified torques.

• If a part is dropped, replace it with a new one and discard the dropped part as invisible damage may be caused.

1.Install the ETC module in the reverse order of removal.

1.Hold the start button or ignition key at the IG ON position for 1 minute.

2. After starting the engine, keep the idle state for 15 minutes.

3. Turn the ignition key or the start button off and hold for 1 minute.

4. Re-start the engine and check the idle roughness.

• If the ETC module learning procedure is not performed after replacing or reinstalling it, MIL illumination with DTCs may occur.

Engine Control Module (ECM)

Engine Control Module (ECM)

- ECM Terminal And Input/Output signal

ECM Terminal Function

Connector [A]

Pin NoDescription

1Integrated Thermal Mangement Module (ITM) Motor (+)

2Integrated Thermal Mangement Module (ITM) ...

Manifold Absolute Pressure Sensor (MAPS)

Manifold Absolute Pressure Sensor (MAPS)

- Description

Manifold Absolute Pressure Sensor (MAPS) is a speed-density type sensor

installed on the surge tank. It senses absolute pressure of the surge

tank and transfers the analog signal ...

Other information:

Hyundai Santa Cruz 2021-2025 Owners Manual: Check Tire Inflation Pressure

Check your tires, including the spare

tire, once a month or more.

How to check

Use a good quality tire pressure

gauge to check tire pressure. You

can not tell if your tires are properly

inflated simply by looking at them.

Radial tires may look properly

inflated when they are underinflated.

Rem ...

Hyundai Santa Cruz (NX4A OB) 2021-2025 Service Manual: Front Driveshaft

- Components

[2.5 GDI]

1. Front driveshaft (LH)2. Innershaft bearing bracket3. Front driveshaft (RH)

[2.5 T-GDI]

1. Front driveshaft (LH)2. Innershaft bearing bracket3. Front driveshaft (RH)

- Removal

• When lifting a vehicle using a lift, be careful not to ...