Hyundai Santa Cruz: General Information / General Tightening Torque Table

- Tightening Torque Table of Standard Parts

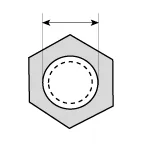

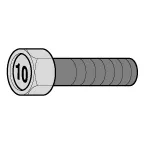

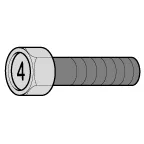

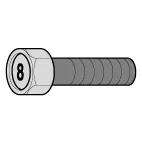

| BOLT (Nominal diameter) | NUT (Nominal diameter) | ||

|

|

|

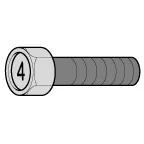

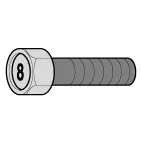

| BOLT/ NUT Normal screw | Torque Nm (kg.m, Ib-ft) | |||

Nominal diameter. (mm) |

Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.8 (0.031) | 2.0 - 3.0 (0.2 - 0.3, 1.4 - 2.2) | 4.9 - 6.9 (0.5 - 0.7, 3.6 - 5.1) | 7.8 - 10.8 (0.8 - 1.1, 5.8 - 8.0) |

| M6 | 1 (0.039) | 2.9 - 4.9 (0.3 - 0.5, 2.2 - 3.6) | 8.8 - 12.7 (0.9 - 1.3, 6.5 - 9.4) | 13.7 - 18.6 (1.4 - 1.9, 10.1 - 13.7) |

| M8 | 1.25 (0.049) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) | 22.6 - 30.4 (2.3 - 3.1, 16.6 - 22.4) | 33.3 - 44.1 (3.4 - 4.5, 24.6 - 32.5) |

| M10 | 1.5 (0.059) | 16.7 - 22.6 (1.7 - 2.3, 12.3 - 16.6) | 45.1 - 60.8 (4.6 - 6.2, 33.3 - 44.8) | 65.7 - 88.3 (6.7 - 9.0, 48.5 - 65.1) |

| M12 | 1.75 (0.068) | 29.4 - 39.2 (3.0 - 4.0, 21.7 - 28.9) | 78.5 - 105.9 (8.0 - 10.8, 57.9 - 78.1) | 114.7 - 154.9 (11.7 - 15.8, 84.6 - 114.3) |

| M14 | 2 (0.078) | 47.1 - 63.7 (4.8 - 6.5, 34.7 - 47.0) | 125.5 - 169.7 (12.8 - 17.3, 92.6 - 125.1) | 183.4 - 249.1 (18.7 - 25.4, 135.3 - 183.7) |

| M16 | 2 (0.078) | 73.5 - 100.0 (7.5 - 10.2, 54.2 - 73.8) | 197.1 - 266.7 (20.1 - 27.2, 145.4 - 196.7) | 288.3 - 390.3 (29.4 - 39.8, 212.7 - 287.9) |

| M20 | 2.5 (0.098) | 144.2 - 195.2 (14.7 - 19.9, 106.3 - 143.9) | 396.2 - 535.4 (40.4 - 54.6, 292.2 - 394.9) | 565.8 - 764.9 (57.7 - 78.0, 417.3 - 564.2) |

| M24 | 3 (0.118) | 249.1 - 337.3 (25.4 - 34.4, 183.7 - 248.8) | 687.4 - 929.7 (70.1 - 94.8, 507.0 - 685.7) | 975.8 - 1320.0 (99.5 - 134.6, 719.7 - 973.6) |

| M30 | 3.5 (0.137) | 499.2 - 674.7 (50.9 - 68.8, 368.2 - 497.6) | 1372.9 - 1858.4 (140.0 - 189.5, 1012.6 - 1370.7) | 1956.4 - 2647.8 (199.5 - 270.0, 1443.0 - 1952.9) |

| BOLT/ NUT Thin screw | Torque Nm (kg.m, Ib-ft) | |||

| Nominal diameter. (mm) |

Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.5 (0.019) | 2.0 - 3.0 (0.2 - 0.3, 1.4 - 2.2) | 5.9 - 8.8 (0.6 - 0.9, 4.3 - 6.5) | 8.8 - 12.7 (0.9 - 1.3, 6.5 - 9.4) |

| M6 | 0.75 (0.029) | 3.9 - 4.9 (0.4 - 0.5, 2.9 - 3.6) | 9.8 - 13.7 (1.0 - 1.4, 7.2 - 10.1) | 14.7 - 20.6 (1.5 - 2.1, 10.8 - 15.2) |

| M8 | 1 (0.039) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) | 24.5 - 32.4 (2.5 - 3.3, 18.1 - 23.9) | 35.3 - 48.1 (3.6 - 4.9, 26.0 - 35.4) |

| M10 | 1.25 (0.049) | 17.7 - 23.5 (1.8 - 2.4, 13.0 - 17.4) | 47.1 - 63.7 (4.8 - 6.5, 34.7 - 47.0) | 69.6 - 94.1 (7.1 - 9.6, 51.4 - 69.4) |

| M12 | 1.25 (0.049) | 32.4 - 44.1 (3.3 - 4.5, 23.9 - 32.5) | 86.3 - 117.7 (8.8 - 12.0, 63.7 - 86.8) | 127.5 - 172.6 (13.0 - 17.6, 94.0 - 127.3) |

| M14 | 1.5 (0.059) | 51.0 - 69.6 (5.2 - 7.1, 37.6 - 51.4) | 136.3 - 185.3 (13.9 - 18.9, 100.5 - 136.7) | 201.0 - 271.6 (20.5 - 27.7, 148.3 - 200.4) |

| M16 | 1.5 (0.059) | 79.4 - 107.9 (8.1 - 11.0, 58.6 - 79.6) | 211.8 - 286.4 (21.6 - 29.2, 156.2 - 211.2) | 311.8 - 421.7 (31.8 - 43.0, 230.0 - 311.0) |

| M20 | 1.5 (0.059) | 163.8 - 221.6 (16.7 - 22.6, 120.8 - 163.5) | 448.2 - 607.0 (45.7 - 61.9, 330.5 - 447.7) | 639.4 - 864.9 (65.2 - 88.2, 471.6 - 638.0) |

| M24 | 2 (0.078) | 276.5 - 373.6 (28.2 - 38.1, 204.0 - 275.6) | 759.0 - 1026.8 (77.4 - 104.7, 559.8 - 757.3) | 1080.7 - 1462.2 (110.2 - 149.1, 797.1 - 1078.4) |

| M30 | 2 (0.078) | 562.9 - 762.0 (57.4 - 77.7, 415.2 - 562.0) | 1553.4 - 2102.5 (158.4 - 214.4, 1145.7 - 1550.8) | 2210.4 - 2991.0 (225.4 - 305.0, 1630.3 - 2206.1) |

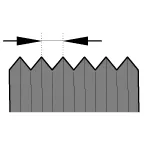

| Flange BOLT (Nominal diameter) | Flange NUT (Nominal diameter) | ||

|

|

|

| Flange BOLT/ NUT Normal screw | Torque Nm (kg.m, Ib-ft) | |||

| Nominal diameter. (mm) |

Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.8 (0.031) | 2.0 - 2.9 (0.2 - 0.3, 1.4 - 2.2) | 5.9 - 7.8 (0.6 - 0.8, 4.3 - 5.8) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) |

| M6 | 1 (0.039) | 3.9 - 4.9 (0.4 - 0.5, 2.9 - 3.6) | 9.8 - 13.7 (1.0 - 1.4, 7.2 - 10.1) | 14.7 - 19.6 (1.5 - 2.0, 10.8 - 14.5) |

| M8 | 1.25 (0.049) | 8.8 - 11.8 (0.9 - 1.2, 6.5 - 8.7) | 24.5 - 32.4 (2.5 - 3.3, 18.1 - 23.9) | 35.3 - 48.1 (3.6 - 4.9, 26.0 - 35.4) |

| M10 | 1.5 (0.059) | 17.7 - 24.5 (1.8 - 2.5, 13.0 - 18.1) | 48.1 - 65.7 (4.9 - 6.7, 35.4 - 48.5) | 70.6 - 96.1 (7.2 - 9.8, 52.1 - 70.9) |

| M12 | 1.75 (0.068) | 31.4 - 43.1 (3.2 - 4.4, 23.1 - 31.8) | 84.3 - 113.8 (8.6 - 11.6, 62.2 - 83.9) | 123.6 - 167.7 (12.6 - 17.1, 91.1 - 123.7) |

| M14 | 2 (0.078) | 51.0 - 68.6 (5.2 - 7.0, 37.6 - 50.6) | 135.3 - 182.4 (13.8 - 18.6, 99.8 - 134.5) | 198.1 - 268.7 (20.2 - 27.4, 146.1 - 198.2) |

| M16 | 2 (0.078) | 79.4 - 107.9 (8.1 - 11.0, 58.6 - 79.6) | 212.8 - 288.3 (21.7 - 29.4, 157.0 - 212.7) | 311.8 - 421.7 (31.8 - 43.0, 230.0 - 311.0) |

| Flange BOLT/ NUT Thin screw | Torque Nm (kg.m, Ib-ft) | |||

Nominal diameter. (mm) |

Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

|

|

|

| M5 | 0.5 (0.019) | 2.9 - 2.9 (0.3 - 0.3, 2.2 - 2.2) | 6.9 - 8.8 (0.7 - 0.9, 5.1 - 6.5) | 9.8 - 13.7 (1.0 - 1.4, 7.2 - 10.1) |

| M6 | 0.75 (0.029) | 3.9 - 5.9 (0.4 - 0.6, 2.9 - 4.3) | 10.8 - 14.7 (1.1 - 1.5, 8.0 - 10.8) | 16.7 - 21.6 (1.7 - 2.2, 12.3 - 15.9) |

| M8 | 1 (0.039) | 9.8 - 12.7 (1.0 - 1.3, 7.2 - 9.4) | 26.5 - 35.3 (2.7 - 3.6, 19.5 - 26.0) | 38.2 - 52.0 (3.9 - 5.3, 28.2 - 38.3) |

| M10 | 1.25 (0.049) | 19.6 - 25.5 (2.0 - 2.6, 14.5 - 18.8) | 51.0 - 68.6 (5.2 - 7.0, 37.6 - 50.6) | 75.5 - 102.0 (7.7 - 10.4, 55.7 - 75.2) |

| M12 | 1.25 (0.049) | 35.3 - 48.1 (3.6 - 4.9, 26.0 - 35.4) | 94.1 - 126.5 (9.6 - 12.9, 69.4 - 93.3) | 138.3 - 186.3 (14.1 - 19.0, 102.0 - 137.4) |

| M14 | 1.5 (0.059) | 55.9 - 75.5 (5.7 - 7.7, 41.2 - 55.7) | 148.1 - 200.1 (15.1 - 20.4, 109.2 - 147.6) | 216.7 - 293.2 (22.1 - 29.9, 159.8 - 216.3) |

| M16 | 1.5 (0.059) | 86.3 - 116.7 (8.8 - 11.9, 63.7 - 86.1) | 229.5 - 309.9 (23.4 - 31.6, 169.3 - 228.6) | 336.4 - 455.0 (34.3 - 46.4, 248.1 - 335.6) |

1)The torques shown in the table are standard values under the following conditions.

• Nuts and bolts are made of galvanized steel bar.

• Galvanized plain steel washers are inserted.

• All nuts, bolts and plain washers are dry.

2)The torques shown in the table are not applicable.

• When spring washers, toothed washers and the like are inserted.

• If plastic parts are fastened.

• If self-tapping screws or self-locking nuts are used.

• If threads and surfaces are coated with oil.

Other information:

Hyundai Santa Cruz (NX4A OB) 2021-2025 Service Manual: AVN Keyboard Assembly

- Components

- Removal

1.Disconnct the negative (-) battery terminal.

2.Remove the front monitor lower cover (A).

3.Remove the front monitor lower cover after disconnecting the mood lamp connector (A).

4.Remove front monitor side cover (A) and (B).

5.Remove the front moni ...

Hyundai Santa Cruz (NX4A OB) 2021-2025 Service Manual: Parking/View Switch

- Removal

• When removing with a flat-tip screwdriver or remover, wrap protective tape around the tools to prevent damage to components.

• Put on gloves to prevent hand injuries.

• Take care not to bend or scratch the trim and panels.

1.Discon ...